[News Focus] From yoga pants to electric cars, Hyosung gets a boost in materials business

By Kim Byung-wookPublished : Feb. 2, 2021 - 16:24

South Korean textile and chemical conglomerate Hyosung Group is gaining a double boost from the prolonged pandemic and the global transition to electric and hydrogen vehicles.

Hyosung TNC, the fiber production unit of Hyosung Group and the world’s No. 1 spandex producer by capacity, is witnessing a surge in spandex sales as more people choose to work and exercise at home.

“Due to the COVID-19 outbreak, people are spending more time at home, for telecommuting for instance, and the demand has spiked for ‘homewear’ and ‘athleisure’ outfits,” said eBest Securities analyst Anna Lee.

Analysts from Daishin Securities and Hana Financial Investment further point out that spandex sales, which are backed by strong demand for yoga outfits and leggings, can be expected to enjoy a further boost as demand in the fashion industry recovers this year after being depressed throughout the pandemic.

The global surge in spandex sales coincided with the pandemic. In China, the world’s largest exporter of spandex, it took just eight days on average to convert spandex inventory to sales last month, according to the China Chemical Fiber Group. In contrast, the comparable figures stood at 60 days in April and 50 days in July.

On Monday, Hyosung TNC’s stock price hit a record high of 389,000 won ($348.50).

In addition to spandex, Hyosung TNC is exploring business opportunities with Regen, an eco-friendly fiber made of recycled plastic.

Hyosung TNC’s Regen fiber is securing heavyweight clients at a fast pace, including Osprey and the North Face. Expectations are running high as global demand for recycled polyester has been increasing since 2019, when 150 global brands -- Gucci, Balenciaga and Nike among them -- inked the G-7 Fashion Pact to tackle climate change.

Since the first quarter of last year Hyosung TNC has been supplying Regen to Osprey, the world’s biggest supplier of outdoor backpacks with a market share of 43 percent. Osprey is expected to introduce its flagship backpack lineup using Regen this spring.

Also, Hyosung TNC signed an agreement with the North Face last month to supply Regen made of discarded plastic bottles collected on Jeju Island. The brand will showcase jackets and T-shirts made of Regen this year.

On Thursday, Hyosung TNC and the Seoul Metropolitan Government joined hands to recycle plastic bottles in the city and produce 100 metric tons of Regen.

Electric, hydrogen vehicle boom

Hyosung Advanced Materials, another affiliate of Hyosung Group, is latching on to the global transition to electric and hydrogen vehicles.

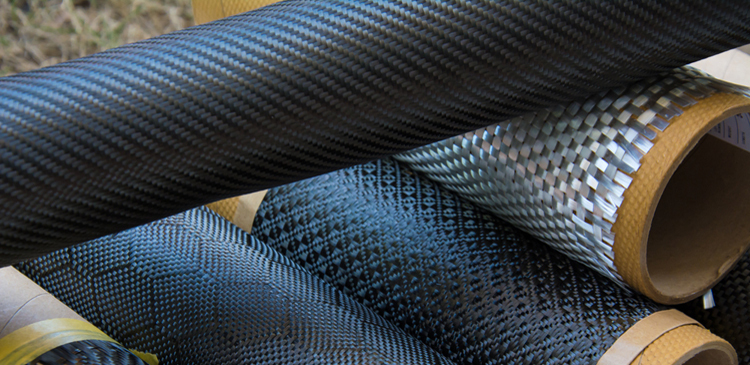

“Hyosung Advanced Materials’ carbon fiber is expected to be applied to Hyundai Motor Group’s hydrogen-powered SUV starting in the second half of this year. Also, the carbon fiber is used in almost all equipment for establishing a hydrogen economy, so its usage will be expanded,” said the eBest analyst Lee.

Carbon fiber, which is four times lighter, 10 times stronger and seven times more elastic than steel, has recently emerged as a key material for fuel tanks inside hydrogen vehicles.

Hyosung Advanced Materials plans to invest 1 trillion won by 2028 to increase the annual production capacity of its carbon fiber plant in Jeonju to 24,000 tons from 2,000 tons as of 2019. The expansion will make the Jeonju plant the world’s biggest on a single site.

“Hyosung Advanced Materials’ carbon fiber is expected to be used for hydrogen tube trailers. Currently, hydrogen tube trailers can only transport small amount of hydrogen as tanks are made of steel. Korea has recently set the development of a carbon fiber hydrogen tank as a government project,” said Kiwoom Securities analyst Lee Dong-wook.

At the same time, Hyosung Advanced Materials aims to inject 61.3 billion won to ramp up the production capacity of aramid to 3,750 tons by the second half of this year from the current 1,250 tons.

Aramid is a thin yellow fiber that is five times more durable than steel. Aramid fibers don’t melt at extremely high temperatures -- between 400 and 500 degrees Celsius. Despite its light weight, an aramid thread just 5 millimeters thick can lift a 2-ton car.

The material has recently drawn the attention of automakers, as reducing the weight of an electric car’s parts to increase their driving distance has become a key challenge.

“A tire consists of layers of different materials, including a layer of steel wires. An aramid layer can replace this steel layer and reduce the weight,” a Hyosung official said.

Aramid fiber is also a vital component of 5G cables. Thanks to its durability, telecommunications firms use the material in optical fibers inside 5G cables to make them strong and prevent them from sagging.

Korea’s telecommunications firms -- SK Telecom, KT, LG U+ and SK Broadband -- aim to invest 25 trillion won to establish a nationwide 5G network by the first half of 2022.

By Kim Byung-wook (kbw@heraldcorp.com)

![[Today’s K-pop] Treasure to publish magazine for debut anniversary](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/07/26/20240726050551_0.jpg&u=)