LCDs to retain edge over OLEDs: expert

Key materials for OLEDs need further improvement before mass production is possible, Jang says

By Korea HeraldPublished : Jan. 22, 2014 - 19:56

Conventional liquid crystal displays will dominate the display market for electronic appliances for the next 10 years as the next-generation organic light-emitting diode technology still needs to be developed, a leading Korean display researcher said.

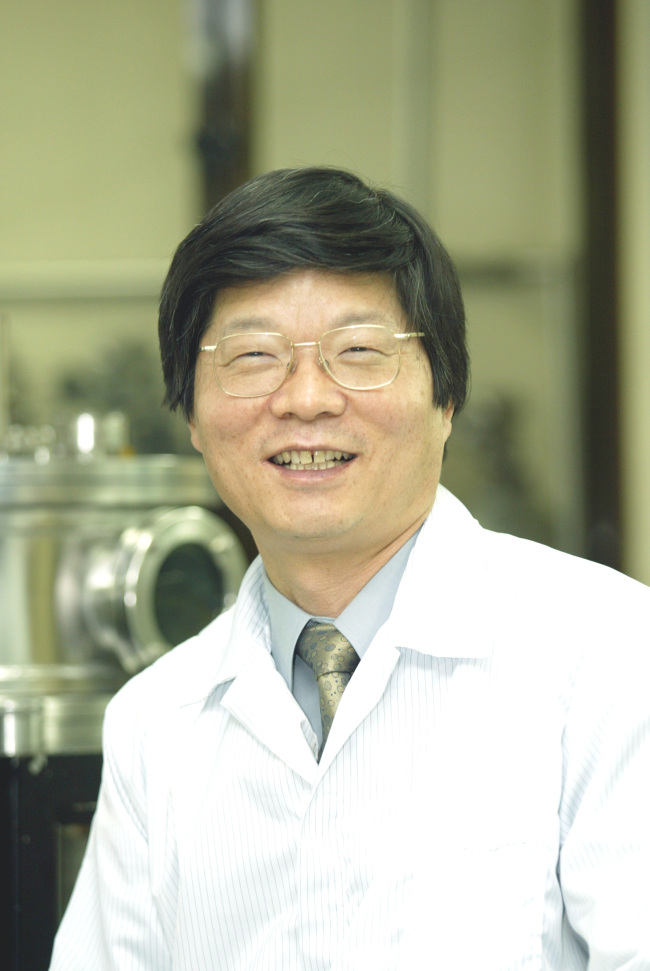

“LCDs will be the most widely used for the next 10 years, as key materials for organic lightemitting diodes have not yet been indigenously and fully developed,” Jang Jin, director of the Advanced Display Research Center at Kyung Hee University told The Korea Herald in an interview.

“Even though there is much hype about OLEDs, especially for flexible and bendable products, Korean tech and materials companies, including Cheil Industries and LG Chem still have a long way to go before they can mass produce them,” Jang said.

“LCDs will be the most widely used for the next 10 years, as key materials for organic lightemitting diodes have not yet been indigenously and fully developed,” Jang Jin, director of the Advanced Display Research Center at Kyung Hee University told The Korea Herald in an interview.

“Even though there is much hype about OLEDs, especially for flexible and bendable products, Korean tech and materials companies, including Cheil Industries and LG Chem still have a long way to go before they can mass produce them,” Jang said.

The director also pointed out that the biggest challenge facing Korean companies is producing next-generation displays without flaws, measured by the yield rate.

The low production yield is why Samsung Electronics and LG Electronics are forced to introduce a limited number of large but expensive OLED TVs.

Further, these firms are finding it difficult to move toward adopting OLEDs for the production of flexible smartphones and wearable gadgets, including Samsung Electronics’ Galaxy Gear, and Apple’s iPhone and iWatch, the display expert noted.

Korea has to further improve two key material components ― thin film encapsulation and plastics ― before the next-generation display panel can replace LCDs.

Given that OLEDs are vulnerable to moisture, thin film encapsulation, the barrier technology that prevents water and oxygen from affecting OLEDs, particularly in flexible products, needs to be improved, Jang explained.

“Also, plastic materials for OLEDs that can better withstand heat need to be developed as well,” he added.

Consumers, however, will be able to see more smartphones featuring flat OLED panels and wearable products with flexible OLEDs as the production yield rate is higher for smaller devices than for bigger products.

Such improvement in key materials would lead to the introduction of rollable displays, which are often said to be the “dream product,” Jang said, adding that as soon as they hit the market, traditional newspapers will be replaced by fully flexible electronic newspapers, according to the professor.

“In about 10 years, people will be able to pull out a rollable display from a drawer and hang it on a wall,” Jang said.

Regarding Chinese display companies such as TCL gaining a competitive edge in the global markets following their recruitment of tech engineers from Taiwan, he said “Chinese displays are no match at the moment for Korean tech giants including Samsung and LG.”

Even though Chinese companies have unveiled curved and flexible TVs at recent electronics shows, their resolutions are not comparable to Korean products.

But he conceded that Chinese companies have surely become the biggest threat to the Korean display industry.

“Korea has to work to promote a company that focuses on developing core technologies that others cannot easily copy, like Intel in the semiconductor industry,” said Jang.

By Kim Young-won (wone0102@heraldcorp.com)

-

Articles by Korea Herald

![[Hello India] Hyundai Motor vows to boost 'clean mobility' in India](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/25/20240425050672_0.jpg&u=)