[Exclusive] Samsung SDI, LG Energy Solution complete development of 4680 cell samples, eye Tesla orders

By Kim Byung-wookPublished : July 13, 2021 - 11:23

Samsung SDI and LG Energy Solution have finished developing samples of larger and more powerful “4680” battery cells, a type first presented by Tesla last year, in an apparent effort to win contracts from the global electric vehicle leader, a source said Tuesday.

“Samsung SDI and LG Energy Solution have developed samples of cylindrical 4680 cells and are currently conducting various tests at their facilities to verify their structural integrity. Also, they have provided specifications of their 4680 cells to their vendors,” a high-ranking industry official with knowledge of the matter told The Korea Herald.

At the annual shareholders meeting held in March, Samsung SDI President and CEO Jun Young-hyun told The Korea Herald that the firm was developing a new cylindrical cell bigger than its existing 2170 model, but declined to confirm its exact specifications.

In April, it was revealed that Samsung SDI and Hyundai Motor were co- developing next-generation cylindrical cells, bigger than 2170 cells but smaller than 4680 cells, designed exclusively for the automaker’s future hybrid electric vehicle models.

Industry officials say there is room for Samsung SDI to join Tesla’s existing battery cell suppliers -- LG Energy Solution, Panasonic and CATL -- considering CATL doesn’t manufacture cylindrical battery cells.

Samsung SDI is currently planning to build its first battery cell plant in the US. Securing 4680 cell orders from Tesla would add impetus to their expansion plan.

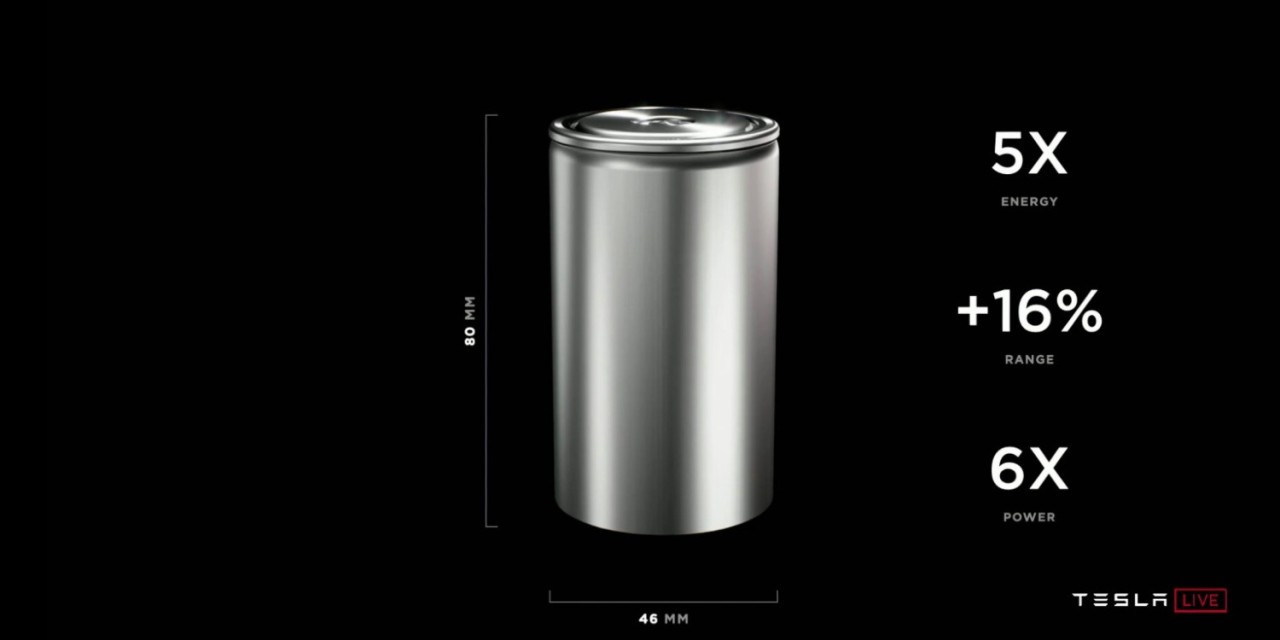

First presented at Tesla’s Battery Day in September, the 4680 cells are expected to be mounted on the Tesla Model Y that will be manufactured in Texas in 2023. The numbers refer to the size of the cells -- 46 millimeters in diameter and 80 millimeters in height. The larger units are cheaper and more efficient, allowing for smaller or longer-range battery packs.

Sun Belt, a southern region comprising 15 states, is mentioned as a promising site for Samsung SDI’s envisioned battery cell plant.

Meanwhile, LG Energy Solution has hinted at developing 4680 cells during a conference call last October, but has since denied having completed the development of a prototype.

In February, local brokerage house Meritz Securities said in a report that LG Energy Solution would have “completed the world’s first mass-production of 4680 cells and supplied them to its clients.”

In March, Reuters reported that LG Energy Solution plans to make 4680 cells in 2023 and is considering potential production sites in the US or Europe.

In the same month, LG Energy Solution announced it would invest more than 5 trillion won ($4.37 billion) and build at least two new battery cells in the US by 2025 to produce pouch and “cylindrical” cells as well as cells for energy storage systems.

LG Energy Solution currently supplies 2170 cells to Tesla Model 3 and Model Y vehicles made in China. LG Energy Solution hasn’t secured an official deal to produce 4680 cells for Tesla yet so it is unclear whether the company will play a bigger role in Tesla’s battery cell supply chain outside of China.

Upon worries that Tesla’s in-house battery production intends to cut ties from existing battery suppliers including LG Energy Solution, CATL and Panasonic, Tesla CEO Elon Musk explained that the company was taking action on its own as significant battery cell shortages are expected despite its cell suppliers going at maximum speed.

Though Tesla hasn’t officially given production orders of 4680 cells to its battery cell suppliers, Panasonic -- Tesla’s oldest battery partner -- is preparing to produce 4680 cells.

Last month, Panasonic’s new CEO Yuki Kusumi said the firm was ready to make a “large investment” to produce Tesla’s 4680 cells if its current prototype production line is successful. Panasonic is in the process of setting up the prototype production line.

The CEO didn’t elaborate on the size of the potential investment, but billions of dollars are often required to deploy significant battery cell production capacity, such as a dozen gigawatt-hours per year.

![[From the Scene] Monks, Buddhists hail return of remains of Buddhas](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/19/20240419050617_0.jpg&u=20240419175937)

![[From the Scene] Monks, Buddhists hail return of remains of Buddhas](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=652&simg=/content/image/2024/04/19/20240419050617_0.jpg&u=20240419175937)

![[KH Explains] Hyundai's full hybrid edge to pay off amid slow transition to pure EVs](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=652&simg=/content/image/2024/04/18/20240418050645_0.jpg&u=20240419100350)

![[Today’s K-pop] Illit drops debut single remix](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/19/20240419050612_0.jpg&u=)