Hyundai Steel applies AI, big data for advanced production management

By Kim Da-solPublished : June 28, 2022 - 15:45

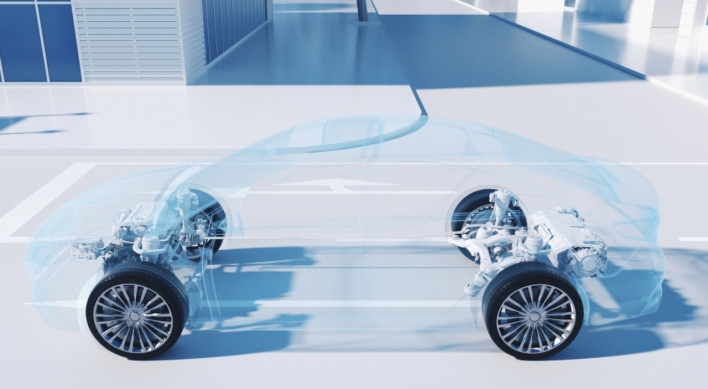

Hyundai Steel has built a so-called Smart Enterprise system, an advanced management program that oversees from production to sales and infrastructure management through AI technology, officials said Tuesday.

The new system features AI technology and big data to advance the entire process from manufacturing to sales at steel mills, Hyundai Steel said.

“The company will complete the Smart Enterprise system by forming the most optimized decision-making process centered in customers by merging data through technology,” said an official.

A task force team has been set up to create a platform that gathers and merges data to innovate the overall manufacturing, infrastructure system and production management at its workplace. The full operation of the new system will be readied by 2025, the company added.

An AI-based production system will be also implemented at the steelmaker’s factories, by upgrading instrument control modules for processes like steelmaking and steel rolling so they can more accurately control and measure materials for production. The company said it has been working on the development of instrument control module, which will learn itself how to merge with other controlling data on factory operation. Such high-tech module will be also applied to other business operations so it can make accurate decision based on data, and also monitor errors during the entire production process.

Hyundai Steel has joined hands with local firms to invest in developing a virtual sensor technology called PTOP-VsensorTM solution.

It is a machine learning-based software program that can sync with data gathered via physical sensors installed inside heating furnaces at steel mills. While physical sensors are prone to risks and errors due to emissions exhausted inside the furnace, using software to predict scenarios and control modules are not only safe but enhances fuel efficiency, according to the firm.

![[Kim Seong-kon] Democracy and the future of South Korea](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/16/20240416050802_0.jpg&u=)

![[Today’s K-pop] Zico drops snippet of collaboration with Jennie](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/18/20240418050702_0.jpg&u=)