Hyundai Motor unveils new CVVD engine valve control technology, a world first

By Kim Da-solPublished : July 3, 2019 - 16:36

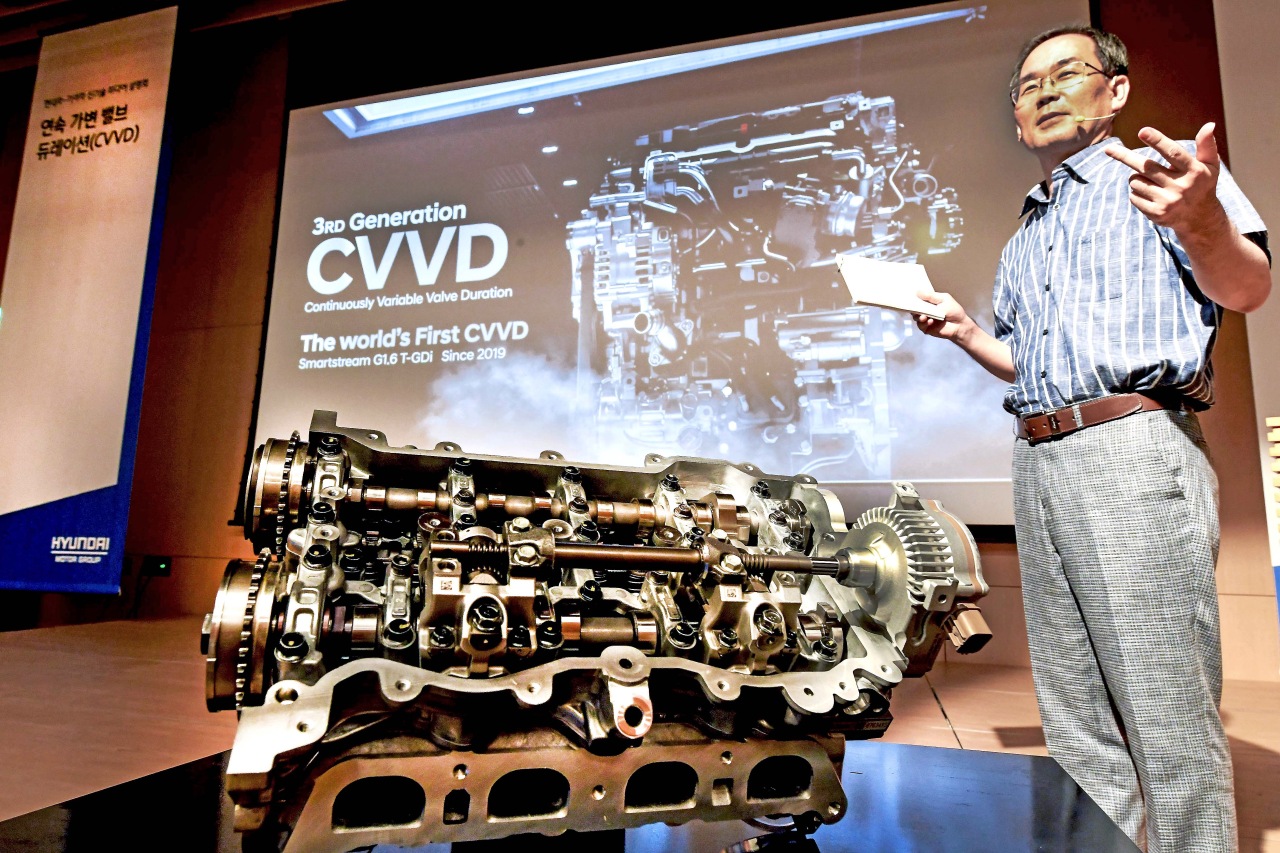

Hyundai Motor Group announced Wednesday that it had become the first company in the world to develop a technology called Continuously Variable Valve Duration, which will improve engine performance and fuel efficiency once the automaker begins mass-producing CVVD-equipped engines for use in Hyundai and Kia cars later this year.

According to the company, CVVD technology enhances the function of the engine by optimizing the timing of the opening and closing of the valve at all four stages of its power production cycle -- intake, compression, expansion and exhaust. The timing and the depth of the valve opening are important because it controls the amount of air inside the cylinder, which affects engine performance and fuel efficiency, the company explained.

According to the company, CVVD technology enhances the function of the engine by optimizing the timing of the opening and closing of the valve at all four stages of its power production cycle -- intake, compression, expansion and exhaust. The timing and the depth of the valve opening are important because it controls the amount of air inside the cylinder, which affects engine performance and fuel efficiency, the company explained.

Hyundai’s new CVVD technology makes it possible to adjust the timing and duration of valve opening and closing when a vehicle is driving at a constant speed and requires low engine output, in order to increase fuel efficiency. For instance, when the car speeds up and engine output is high, the intake valve is closed faster so the amount of air needed for combustion is at the maximum level, enhancing torque to improve acceleration.

Existing engine valve control technologies -- CVVT and CVVL, which control the timing and volume of air through a thermally efficient Atkinson cycle -- could not adjust the duration of valve opening and closing or respond to different driving situations.

The automaker said it had developed the technology with three key concepts in mind -- efficiency, performance and eco-friendliness -- and that CVVD technology improved engine performance by 4 percent and fuel efficiency by 5 percent, while reducing emissions by 12 percent compared with CVVT or CVVL.

“The development of the CVVD technology is a good example of how Hyundai Motor Group is strengthening our powertrain technology,” Albert Biermann, president and head of the research and development division at Hyundai Motor Group, said in a statement.

“We will continue our innovation efforts to bring forth paradigm shifts and ensure sustainability of our business model.”

Hyundai said it will begin applying CVVD technology to its new models, including the Sonana Turbo, which will hit the market in the latter half of this year.

Sonata Turbo will run on the CVVD-equipped Smartstream G1.6 T-GDi, the automaker’s new four-cylinder gasoline turbo-petrol engine, which was also unveiled Wednesday.

The engine, which features various new technologies including an integrated thermal management system, produces a maximum of 180 horsepower and up to 27 kilogram-meters of torque.

By Kim Da-sol (ddd@heraldcorp.com)

![[Graphic News] More Koreans say they plan long-distance trips this year](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/17/20240417050828_0.gif&u=)

![[KH Explains] Hyundai's full hybrid edge to pay off amid slow transition to pure EVs](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/18/20240418050645_0.jpg&u=20240419100350)

![[From the Scene] Monks, Buddhists hail return of remains of Buddhas](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=652&simg=/content/image/2024/04/19/20240419050617_0.jpg&u=20240419175937)

![[KH Explains] Hyundai's full hybrid edge to pay off amid slow transition to pure EVs](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=652&simg=/content/image/2024/04/18/20240418050645_0.jpg&u=20240419100350)

![[Today’s K-pop] Illit drops debut single remix](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/19/20240419050612_0.jpg&u=)