LG Innotek to mass produce ultra-hard thermoelectric chips next year

By Song Su-hyunPublished : June 12, 2018 - 14:02

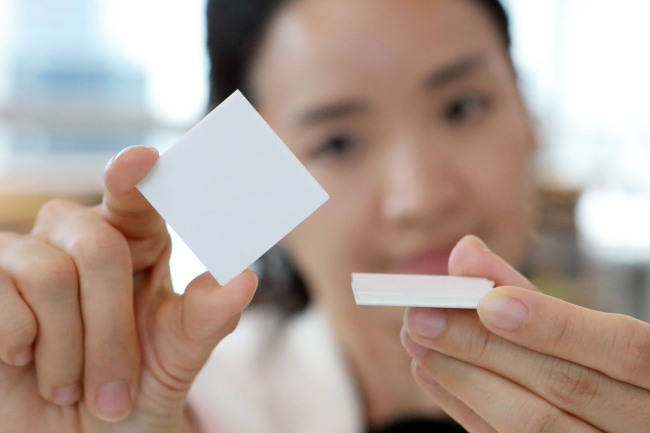

LG Innotek, an electric parts manufacturing subsidiary of LG Electronics, said Tuesday it has completed a facility for mass production of nanometer-class thermoelectric chips for a variety of applications from home appliances to vehicles and vessels.

The company has established a production line for the product in Gumi, North Gyeongsang Province, and will embark on mass production next year, it said.

Thermoelectric chips are known as innovative semiconductors that produce power by heating and cooling, and using temperature differences during the processes.

The company has established a production line for the product in Gumi, North Gyeongsang Province, and will embark on mass production next year, it said.

Thermoelectric chips are known as innovative semiconductors that produce power by heating and cooling, and using temperature differences during the processes.

LG Innotek used its exclusive material for development of the thermoelectric chip, which is a nano polycrystalline material that has a nanometer-class structure and therefore is 2.5 times harder than those with single crystals.

The material also helps reduce power consumption by up to 30 percent as it improves cooling efficiency by 30 percent.

According to the company, the upcoming thermoelectric chip will help build smaller home appliances and reduce noise from their operations.

It can also be applied for telecommunications equipment to help maintain the temperature of parts in the equipment and reduce losses to data.

In automobiles and ships, the thermoelectric chip will reuse used heat from the vehicles, contributing to reducing toxic emissions.

A diesel-run car will see fuel efficiency improve by 9 to 12 percent by adopting the chip, the company said.

“The market for thermoelectric chips is expected to see rapid growth as there are many areas of applications,” an official at LG Innotek said.

The company will hold a tech forum on thermoelectric chips at LG Science Park in Magok, western Seoul, next Wednesday.

By Song Su-hyun (song@heraldcorp.com)

![[Exclusive] Korean military set to ban iPhones over 'security' concerns](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/23/20240423050599_0.jpg&u=20240423183955)

![[Graphic News] 77% of young Koreans still financially dependent](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/22/20240422050762_0.gif&u=)

![[Pressure points] Leggings in public: Fashion statement or social faux pas?](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/23/20240423050669_0.jpg&u=)