Hyundai to widen access to performance cars

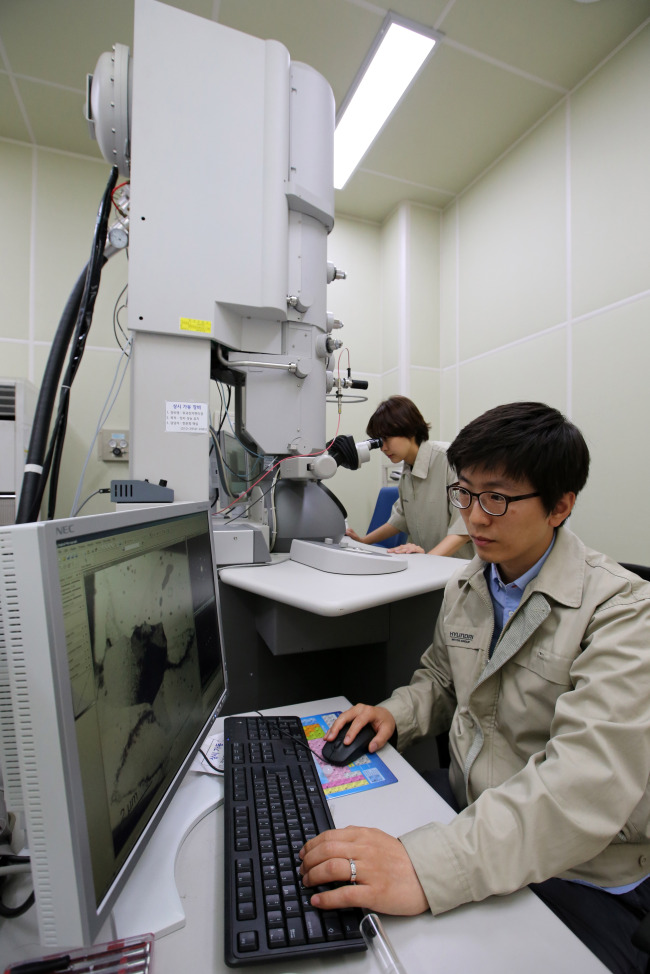

Engineers at Hyundai Motor’s R&D center strive to enhance driving dynamics, surpass carmaker’s past image as fast follower via N project

By Korea HeraldPublished : July 19, 2017 - 16:13

HWASEONG, Gyeonggi Province -- The N project by Hyundai Motor does not ring a bell at first glance, despite its sleek slogan of high-performance driving.

But when taking a ride in the passenger seat for a test drive of the Racing Midship, the flagship symbol of the project, one begins to understand what South Korea’s largest automaker is setting out to achieve.

Dubbed N project’s “rolling test-lab,” the Veloster-based RM16 is the fastest car by the South Korean carmaker to date, as it surpasses 100 kilometers per hour in 4.7 seconds.

Although the car might not be the fastest in the world, the N project is a platform for engineers at Hyundai Global R&D Center in Hwaseong, some 50 kilometers south of Seoul, to take the carmaker’s driving technology to a level it has never reached before.

But when taking a ride in the passenger seat for a test drive of the Racing Midship, the flagship symbol of the project, one begins to understand what South Korea’s largest automaker is setting out to achieve.

Dubbed N project’s “rolling test-lab,” the Veloster-based RM16 is the fastest car by the South Korean carmaker to date, as it surpasses 100 kilometers per hour in 4.7 seconds.

Although the car might not be the fastest in the world, the N project is a platform for engineers at Hyundai Global R&D Center in Hwaseong, some 50 kilometers south of Seoul, to take the carmaker’s driving technology to a level it has never reached before.

“Making a car that goes further, faster by maximizing driving performance is the goal of the N project,” said Im Se-bin, director of the high-performance vehicle development group at Hyundai Motor. “We are confident that our high-performance cars that are currently in test drive are almost as high in quality as performance cars made by German premium automakers,” he said.

A self-developed Theta II 2.0 Turbo GDI engine is placed at the back of the car for better weight distribution. The RM16 is 180 kilograms lighter than its predecessor RM 14 through the use of aluminum for the car body.

With a Hyundai engineer who has a racing license behind the wheel, the RM 16 made stable turns around sharp corners on an X-shaped circuit, which means the passenger must endure a G-force of 1.4 Gs at about 120 kph, higher than the 0.8 G experienced during daily driving.

The RM 16 produces maximum 300 horsepower and a maximum torque of 39 kilogram-meters, he said, adding that it might have cost about 1 billion won to manufacture a RM series vehicle.

The carmaker has three RM vehicles so far, numbered by the year they were created. The RM16 that The Korea Herald rode in was unveiled during the Busan Motor Show in 2016.

Since 2012, Hyundai has been working on the development of performance models, including the N brand to enhance its brand image and to bet its future on high-functioning vehicles amid fierce competition heightened by the invasion of tech companies in the auto industry.

The project has been led by Albert Biermann, a former BMW senior engineer who led the M project, before joining Hyundai in 2014.

Although it was a late starter, Hyundai has added its own characteristics to the project by creating high functioning vehicles for the mass market.

“We should be able to make super cars not only for a limited group of people. We want to make high-functioning race-track-capable cars that are fun and also affordable to drive,” Im said, while looking down at a track from an observatory deck of Hyundai’s R&D complex.

The Hyundai Global R&D center, also known as Namyang Institute, is where the N project was born and is being developed. The letter “N” stands for the name of the R&D center and also Germany’s legendary Nurburgring racing track. The carmaker has a test center there.

To target the European market, Hyundai has been sending its high-performance i30 hatchback, codenamed i30N, to a 24-hour endurance race in Germany since last year.

One of the two i30N models ranked 50th this year, a leap from 90th place in the same endurance competition last year.

The models were preproduction versions of the i30N hatchback, the first high-performance car developed under the N project. The high-performance i30N will be unveiled in Europe in October, but not yet in Seoul. The company plans to release the Veloster N in the South Korean market early next year.

Hyundai won market recognition in the US with strong marketing networks and competitive prices, but to expand its presence in Europe, proving the car’s performance and endurance is key.

This is why engineers at Namyang are testing the high-performance vehicles on a round, wet circuit made to resemble the road conditions of rainy Europe, said Kim Doo-hyun, a senior engineer at the N Division. A system that quickly controls driving force between wheels on the right and left side helped the RM 16 quickly recover its balance during aggressive cornering on the slippery course, he added.

Built on reclaimed land, the 347 square-kilometer complex is bigger than Seoul’s financial district of Yeouido, said Park Min-yeong, a director at the carmaker’s public relations team. The complex is the heart of Hyundai’s future technology, as it houses engineering labs, design institutes and 70-kilometer tracks in 34 parts. The Namyang center, which has around 12,000 engineers and administrative staff, is the control tower of the carmaker’s evolving technology that connects research facilities in Uiwang and a design studio in Los Angeles.

Inside the complex, there are prototype vehicles covered in black, with engineers compiling data from quality-test labs that check features of the cars from air resistance to suspension.

“It takes about three to four years to complete the checkup. We spend every minute to test thousands of driving features to satisfy customers and to assure them they are driving the safest cars,” Im said, while leaving the pilot prototype manufacturing building that had a slogan that read, “Drive defects to zero.”

“After all these years, I think our hard efforts are paying off,” he said.

In June, Hyundai’s sister company Kia and its luxury sedan brand Genesis became the industry’s top brands in a quality test conducted by J.D. Power and Associates, beating German high-end brand Porsche.

Kia topped the list for the second consecutive year while Genesis ranked second, taking the position previously held by Porsche in the test that measured the number of problems that emerged per 100 vehicles in the first 90 days of driving. Genesis was tested for the first time, the company added.

Despite the improvements in technology and the carmaker’s global status as the world’s fifth-largest carmaker, Hyundai engineers said they had a mission to complete.

“Let’s admit it. Hyundai has grown this much because the company was a fast follower, producing cars that satisfy customers’ needs at affordable prices,” said Kim, the senior engineer at the N division.

“But we won’t be able to survive if we resort to the past image. ... We want to show the world that we are not the fast follower anymore. This probably what the N project is for.”

By Cho Chung-un (christory@heraldcorp.com) and Kim Bo-gyung (lisakim425@heraldcorp.com)

-

Articles by Korea Herald

![[Exclusive] Korean military set to ban iPhones over 'security' concerns](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/23/20240423050599_0.jpg&u=20240423183955)

![[Graphic News] 77% of young Koreans still financially dependent](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/22/20240422050762_0.gif&u=)

![[Pressure points] Leggings in public: Fashion statement or social faux pas?](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/23/20240423050669_0.jpg&u=)